rockwell hardness test introduction|rockwell hardness testing procedure pdf : factory Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on . See more web24 de jul. de 2008 · ↳ Campinas e Região / Acompanhantes de Campinas/SP; ↳ Campinas e Região / Clínicas, Privês, Boates e outros - Campinas/SP; ↳ Bauru; ↳ Sorocaba; ↳ Vale .

{plog:ftitle_list}

Browse through our professionally designed selection of free .

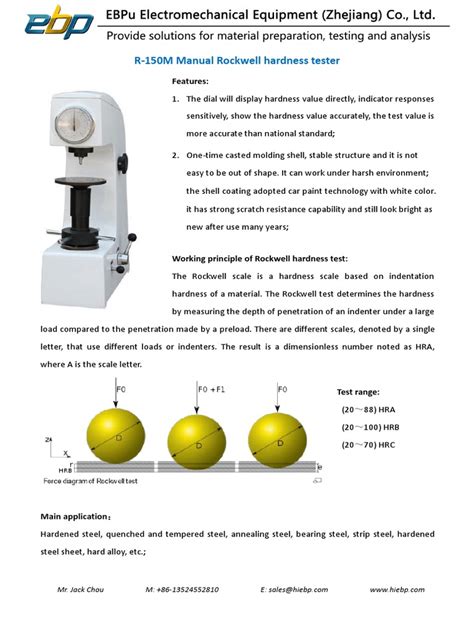

While hardness testing does not provide a direct assessment of product or raw material performance qualities, hardness correlates directly to qualities like strength and wear resistance. Hardness testing is commonly used for material evaluation due to its simplicity and low cost, relative to other assessments of . See moreTypically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on . See moreThe Rockwell hardness number used to evaluate a sample is calculated based on the depth of permanent deformation into the sample, or the . See more

While Rockwell hardness testing can be used on a wide range of samples, there are certain cases with unique considerations. . See moreRockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the .

Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. .

Introduction. What Is Rockwell Hardness Test? The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .Rockwell hardness testing is a method of determining the relative hardness of a material. In this test, hardness is measured by determining the depth of residual penetration by a steel ball .

rockwell hardness testing procedure pdf

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test .INTRODUCTION Hardness is defined as the resistance of a material to permanent deformation such as indentation, wear, abrassion, scratch. Principally, the importance of hardness testing has to do . Vickers and Rockwell hardness test, the results are given to students in the class lab by the Qness hardness test machine in Fig. 4. Different .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). .

In 1919, the Rockwell test was introduced. It has become, by far, the most popular hardness test in use . Introduction to Hardness Testing / 5 Fig. 1 Slip-line-field solutions for a flat-ended two-dimensional punch having a width of 2a. (a) Prandtl’s flow pattern. Flow in unshaded area is downward and to left and right, as indi-Brinell Hardness Test: Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup. There is no such limitation in Rockwell .

Introduction . PHR series portable Rockwell hardness tester complies with the basic designing principles of Rockwell hardness testing in accordance with international standard ISO6508, American Standard ASTM E18 and ASTM E110. The hardness values can be read directly from the Rockwell hardness testers after rapid and accurate operations.

Introduction. Hardness is not a physical property but is characteristic of a material. Still, it is important to check the hardness of objects in manufacturing performance to get better performance of the manufacturing products. . Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or .This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and examining different properties affecting hardness. . 13 Page 2 of 13 Introduction Hardness is a material ability to withstand friction . Now known as Wilson Hardness, the combined expertise of Instron/Wilson, coupled with the subsequent acquisitions of Wolpert Hardness and Reicherter Hardness, have led to the engineering and production of cutting edge hardness systems. The Rockwell test remains as one of the most efficient and widely used hardness test types in use.

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Rockwell Hardness Test Introduction You’ve probably come across the letter and numbers Rc60 or Rc58 when it comes to the quality of tool steel. If you are the sort of person that operates on a need to know basis, it might be enough for you .Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

rockwell hardness testing guide pdf

Introduction. 1 Scope. 2 Normative references. 3 Principle. 4 Symbols, abbreviated terms and designations. 5 Testing machine. 6 Test piece. 7 Procedure. 8 Uncertainty of the results. 9 Test report. . ISO 3738-1, Hardmetals — Rockwell hardness .Rockwell Hardness Test Introduction. Rockwell hardness testing is a commonly used hardness testing method for metal materials. It is based on the elastic and plastic deformation properties of materials under compression. This testing method mainly applies a specific load on the surface of the test material. After the load is released, the .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the .SCOPE. The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . Check out .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive. Objective: Determine the Rockwell hardness number of a given specimen using Rockwell hardness . Introduction of Rockwell hardness. Rockwell hardness is an index to determine the hardness value by the depth of indentation plastic deformation, with 0.002 mm as a hardness unit, expressed as HR. Using different indenters and different test forces in the Rockwell hardness test will produce different combinations (HRA to HR45Y), corresponding .Details of any patent rights identified during the development of the document will be in the Introduction and/or on the ISO list of patent declarations received . ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks;The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.

By using a test block, Rockwell hardness testers can be calibrated for optimal precision. All of Corporation’s test blocks to ASTM E18, ANSI (NCSLZ540-1, (ISO) 10012-1, ISO/IEC 17025, and ISO 6508, and they are certified in our ISO/IEC 17025 accredited laboratory. Each test block is hand lapped and diamond polished to a mirror finish, and . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different materials specimens. (2) Compare the measurements in hardness with each other. INTRODUCTION Hardness can be defined as resistance to penetration, resistance to abrasion, resistance

Introduction. Hardness testing is a fundamental material science technique that measures a material’s ability to resist deformation. It is an essential parameter in the manufacturing industry, as the hardness of a material can affect its strength, durability, and performance. . The Rockwell hardness test is the most commonly used hardness .

wrx cold compression test

wrx compression test cost

All the Tarot versions that we have today derive from the Tar.

rockwell hardness test introduction|rockwell hardness testing procedure pdf